Cherry pickers are versatile aerial work platforms used across industries for elevated tasks․ They enhance efficiency and safety in construction, maintenance, and other high-reach applications․

1․1 What Are Cherry Pickers?

Cherry pickers are aerial work platforms designed to lift personnel and tools to elevated heights safely․ They are either vehicle-mounted or standalone units, often used for tasks requiring high reach․ Common types include boom lifts and scissor lifts․ These machines provide stable access to areas like trees, buildings, and overhead structures․ They are versatile tools for construction, maintenance, and industrial applications, enabling workers to perform tasks efficiently and safely at heights․

1․2 Importance of Cherry Pickers in Various Industries

Cherry pickers play a crucial role in diverse industries, enhancing efficiency and safety․ In construction, they facilitate high-rise tasks like window installation and painting․ Telecommunication and utility sectors rely on them for maintenance of towers and power lines․ Landscaping and arboriculture use cherry pickers for tree pruning and trimming․ Their versatility ensures safe access to elevated areas, minimizing risks and enabling precise work in challenging environments․ This makes them indispensable across multiple sectors for specialized tasks requiring height access․

Safety Considerations

Safety is paramount when operating cherry pickers․ Proper training, equipment inspection, and adherence to safety protocols minimize risks and ensure secure operations in various environments․

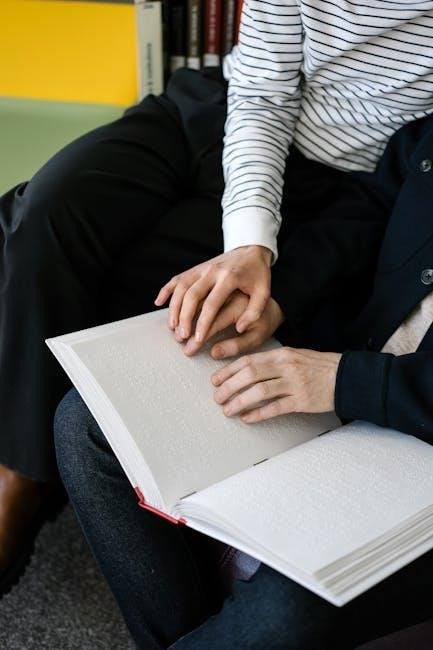

2․1 Personal Protective Equipment (PPE)

Personal Protective Equipment (PPE) is essential for cherry picker operators․ Safety harnesses, hard hats, and non-slip boots prevent injuries from falls and equipment malfunctions․ Operators must ensure proper fit and wear PPE at all times during operation․ Regular inspection of PPE is crucial to maintain its effectiveness․ Employers should provide training on correct usage and ensure compliance with safety standards․ Proper PPE significantly reduces accident risks, making it a cornerstone of workplace safety protocols for aerial lift operations․ Always prioritize PPE to safeguard operators and ensure a secure working environment․

2․2 Operator Training and Certification

Operator training and certification are critical for safe cherry picker operation․ Comprehensive training programs should cover equipment mechanics, safety protocols, and emergency procedures․ Operators must complete both classroom and practical sessions to ensure competence․ Certification must be renewed periodically to stay updated with industry standards․ Employers should verify certifications and ensure only trained personnel operate equipment․ Proper training reduces accidents and ensures compliance with safety regulations․ Neglecting certification can lead to unsafe conditions and legal consequences, making it a non-negotiable requirement for all operators․ Always prioritize certified training for optimal safety and efficiency․

2․3 Emergency Procedures and Safety Protocols

Emergency procedures and safety protocols are essential for minimizing risks when operating cherry pickers․ Operators should be trained to handle malfunctions, power failures, or medical emergencies while aloft․ Establishing clear evacuation plans and rescue procedures is critical․ Regular safety drills ensure preparedness for unexpected situations․ Always maintain communication devices and first aid kits nearby․ Fire extinguishers and emergency stop mechanisms should be easily accessible․ Adhering to these protocols ensures quick response and reduces potential hazards, safeguarding both operators and bystanders in critical scenarios․ Regular reviews of emergency plans are vital to maintain readiness․

Equipment Inspection and Maintenance

Regular inspection and maintenance of cherry pickers ensure optimal performance and safety․ Pre-operational checks, lubrication, and timely repairs prevent mechanical failures and extend equipment lifespan․

Pre-operational checks are essential for ensuring cherry picker safety and functionality․ Operators should inspect hydraulic systems, controls, and safety features before use․ Check for wear and tear on wire ropes and hydraulic hoses, and ensure all emergency stop functions work properly․ Lubricate moving parts to prevent corrosion and maintain smooth operation․ Tires and brake systems must also be examined to guarantee stability and mobility․ A thorough inspection helps identify potential issues early, preventing accidents and downtime during operations․ Regular checks ensure compliance with safety standards and extend equipment lifespan․ A regular maintenance schedule is crucial for ensuring the optimal performance and safety of cherry pickers․ Daily inspections should focus on hydraulic systems, wire ropes, and tires․ Weekly checks should include lubrication of moving parts and examination of control systems․ Monthly maintenance involves thorough inspection of the boom, platform, and safety harnesses․ Adhering to the manufacturer’s guidelines ensures compliance with safety standards and prevents mechanical failures․ Regular servicing also helps extend the equipment’s lifespan and maintains reliability during operations․ Consistent upkeep is vital for safe and efficient use of cherry pickers in any industry․ Common issues with cherry pickers include hydraulic leaks, faulty sensors, and electrical malfunctions․ Symptoms like irregular platform movement or error messages indicate potential problems․ Always refer to the manufacturer’s manual for diagnostic guidance․ Check hydraulic fluid levels and inspect wiring for damage․ Ensure sensors are calibrated correctly and replace worn components promptly․ Addressing issues early prevents equipment downtime and ensures safe operations․ Regular maintenance and inspections help identify and resolve problems before they escalate․ Consult professionals if issues persist to maintain equipment reliability and operator safety․ Efficient cherry picker operation requires adherence to load limits, proper stabilization, and safe height practices․ Operators should always follow manufacturer guidelines to ensure smooth, incident-free performance․ Ensuring load capacity and stability is critical for safe cherry picker operation․ Always check the manufacturer’s specified weight limits to avoid overloading, which can destabilize the equipment․ Proper distribution of loads is essential to maintain balance․ Operators should also ensure the machine is on level ground before raising the platform․ Using outriggers or stabilizing legs can enhance stability, especially on uneven surfaces․ Regular checks of the machine’s balance and tire pressure are recommended to prevent accidents caused by instability or equipment failure during operation․ Navigating cherry pickers across various terrains requires careful planning and assessment․ Operators must evaluate ground conditions, such as rough, uneven, or soft surfaces, to ensure safe movement․ For challenging terrains, machines with four-wheel drive or specialized tires are recommended․ Slow and controlled movements are essential to prevent tipping or losing traction․ Operators should also avoid steep inclines unless specified by the manufacturer․ Proper training and familiarity with the equipment’s capabilities are crucial for safely maneuvering in diverse environments, ensuring both operator and equipment safety while maintaining productivity․ Operating cherry pickers within safe height and reach limits is critical to prevent accidents․ Always adhere to the manufacturer’s specified maximum height and horizontal reach․ Weight distribution and ground stability significantly impact these limits․ On uneven terrain, use outriggers to enhance stability․ Never exceed the machine’s rated capacity, and maintain a safe distance from obstacles like power lines or structures․ Environmental factors, such as wind, can also affect stability at higher elevations․ Continuous monitoring and adjustment are essential to ensure safe operation within prescribed limits․ Hiring qualified operators and ensuring proper training are essential for safe and efficient cherry picker operations․ Always verify certifications and experience before deployment․ Choosing a reliable rental company is crucial for ensuring safety and efficiency․ Look for companies with a strong reputation, experienced staff, and well-maintained equipment․ Verify certifications and compliance with industry safety standards․ Ensure they provide detailed safety documentation and operator training resources․ Compare rental terms, pricing, and availability to meet your specific needs․ A reputable company will also offer round-the-clock support and emergency assistance․ Always inspect equipment before rental to ensure it is in good working condition․ This helps avoid operational issues and ensures a smooth workflow․ Evaluating operator competence is essential for safe and efficient cherry picker operation․ Ensure operators have completed certified training programs and hold valid certifications․ Assess their ability to operate equipment safely by observing practical demonstrations․ Verify understanding of safety protocols, emergency procedures, and equipment limitations․ Regular performance reviews and refresher training can maintain and enhance operator skills․ Competent operators reduce workplace hazards and ensure tasks are completed effectively․ Always prioritize experience and adherence to safety guidelines when evaluating potential operators․ Cherry pickers enhance workplace safety and efficiency when used correctly․ Always follow safety guidelines, ensure proper training, and maintain equipment regularly for optimal performance․ To ensure safe and efficient use of cherry pickers, always conduct pre-operational checks, follow load capacity guidelines, and maintain proper communication with ground personnel․ Operators should stay alert, avoid overreaching, and never exceed height limits․ Regular maintenance and adherence to safety protocols are crucial․ Ensuring operators are well-trained and equipped with proper PPE minimizes risks․ By following these practices, you can maximize productivity while maintaining a safe working environment for everyone involved․3․1 Pre-Operational Checks

3․2 Regular Maintenance Schedule

3․4 Troubleshooting Common Issues

Operational Best Practices

4․1 Load Capacity and Stability

4․2 Navigating Different Terrains

4․3 Safe Heights and Reach Limits

Hiring and Training

5․1 Selecting the Right Rental Company

5․2 Evaluating Operator Competence

6․1 Final Tips for Safe and Efficient Use